4 Water Well Casing Cap

Simmons Manufacturing Company's well caps are made of high quality cast iron, galvanized steel and thermoplastic. Sizes 4' to 6 1/4' casing sizes. A residential casing measures about 4 to 6 inches while a commercial water well tends to be a lot wider in diameter. Well casings are topped with a plastic or aluminum well cap to prevent small animals, insects, and dirt or debris from making it into the well. The cap also has a vent to help control the water pressure during pumping. Shop STAR Water Systems Cast Aluminum Cap in the Water Pump Accessories department at Lowe's.com. This well cap prevents contamination from surface drainage. It is constructed of high quality cast aluminum. . WC6 fits 6”and 6-1/4” I.D. 6 5/8” OD well casing. 1”or 1 1/4” IPS conduit tap and factory installed screen vents. Heavy cast iron body. 20% heavier than any other comparable watertight well caps available. Wide rubber gasket provides positive watertight seal. Blue powder coat paint finish. Individually packaged.

Please note there are no clearance issues using a pitless adapter in a 6″ or larger well casing. But there can be an issue for well casings of 4-5″ in diameter. Most competitor hand pumps cannot be installed beside a submersible in the same well. This is a distinct advantage of the Simple Pump.

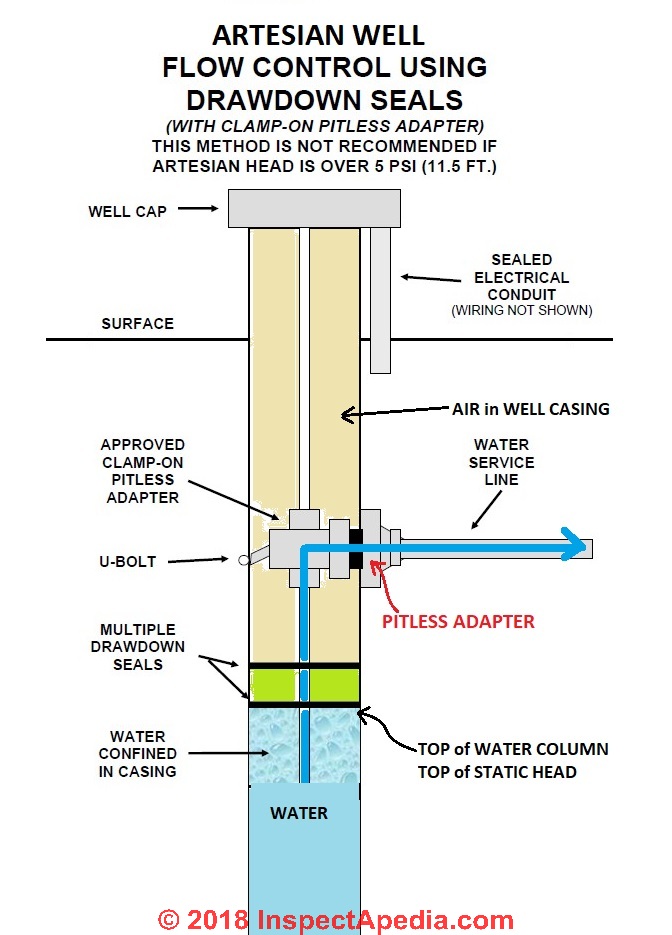

The illustration above is of a typical submersible pump pitless adapter. The Simple Pump pitless adapter is similar in size, but slightly modified to allow the sucker rod to pass thru the top and on up to the pump head.

“I have a submersible with a pitless adapter. Is there enough room in my 4” well casing to install a Simple Pump?”

In order to get the Simple Pump pipe past a pitless adapter that is configured with a submersible, we need 1 3/4″ clearance. And in a 4″ well, there also needs to be the same clearance past any couplers (if used) between each submersible drop pipe. You will need to take some careful measurements to see if there is enough clearance.

“Should I pump out of the top of the well cap or tie into my existing submersible pitless adapter?

If you decide to connect the Simple Pump to your existing underground water line coming out of the submersible pitless adapter, this does require substantially more work than exiting from the well cap. However, there are advantages to going this route.

The Simple Pump pitless is always tied into the water pipe from the submersible at, or very close to, the well head/casing. Doing so eliminates the need for a separate water line from the well casing to the house for the Simple Pump.

To avoid any digging at the well casing, many customers just buy the check valve and gauge. This enables them to hook a drinking water compatible hose from the Simple Pump discharge nipple to a yard hydrant to feed water into the house. They can also hook up to a water spigot on the outside wall of the house or to the drain at the bottom of the pressure tank. All these methods are perfectly acceptable.

4 Water Well Casing Cap

These methods require no digging, but still gives you electrical outage back-up. All you need to do is to detach the hose from the pump head outlet each time you fill your pressure tank. This lets air get into the Simple Pump pump head which allows the water in the pump to descend below freezing level by exiting through the weep hole 48” below.

Water Well Casing Diameter

And therein lies the disadvantage. You must disconnect the hose from the Simple Pump after you have pumped water into the pressure tank. Every time. And if the temperatures are below freezing when you are using the Simple Pump, you will also need to drain the hose and put it away after every use. That can be a real hassle if you are using the Simple Pump (or any other pump for that matter) for more than just a day or so.

So the answer to what is best for you ultimately depends on how cold it is where you live, how often (and how long) you might need to use the Simple pump and whether you want to spend the extra money and time to install the Simple Pump pitless adapter and associated underground check valves and couplings.

We here at Blue Ridge Pumps installed our Simple Pump (with the pitless) in this manner and are extremely pleased with the outcome. There are no worries about disconnecting the hose and rolling it up in the winter every time we use the Simple Pump. Everything is underground, out of sight and out of freezing danger.

4 Inch Well Casing

“Why can’t the Simple Pump work through my existing pipes and pitless adapter?”

The submersible pump pushes water up the pipe to the surface. When it reaches the pitless adapter, the water takes a right-angle turn, goes out through the side of the casing where it connects to a pipe running underground to your house. The pitless is basically just a fancy plumbing joint that redirects the water ninety degrees and fastens securely to the side of the casing so it can carry the weight of the submersible pump, piping and wiring.

The Simple Pump is a completely separate fresh water system that is installed alongside your submersible pump system. We can’t use the submersible pipe because our pipe is more than just a hollow pipe carrying water. Our pipe contains the mechanism (the sucker rods) which connect the lever arm at the top to the pump piston and cylinder at the bottom. Our pipe serves two purpose instead of just carrying water.

There must be some way to get the water in the Simple Pump drop pipe out through the side of the casing while still allowing the sucker rod to pass thru to the top where it is attached to the hand lever or motor. We do so with our specially engineered pitless adapter which allows pumping from the top while diverting the water sideways. See the photo on the upper right.

Once the Simple Pump pitless adapter moves the water out the side of the well casing, the pipe can then be easily connected to the pipe coming from the submersible via a T junction and check valves. This way one pipe moves water from either the submersible pump or the Simple Pump underground to your house. Each branch of the T has a one-way check valve so the operating pump doesn’t pump water DOWN the other branch to the other pump. In other words, the check valves prevent back washing of water down and out the non operational pump.

ALL “COMMON QUESTIONS” PAGES

See also: Glossary of Wells, Pumps and Simple Pump Terms